Unleashing your creativity has never been easier with the use of advanced techniques in hair weave manufacturing. Whether you’re a hairstylist looking to create unique and innovative hairstyles or an individual wanting to express your personal style, these advanced techniques offer endless possibilities. From intricate designs to vibrant colors, the world of hair weave manufacturing has evolved to cater to your wildest imagination. This article explores the fascinating world of advanced techniques in hair weave manufacturing, highlighting the revolutionary methods that are transforming the way we think about hair. Get ready to unleash your creativity and discover a whole new level of self-expression through your hair!

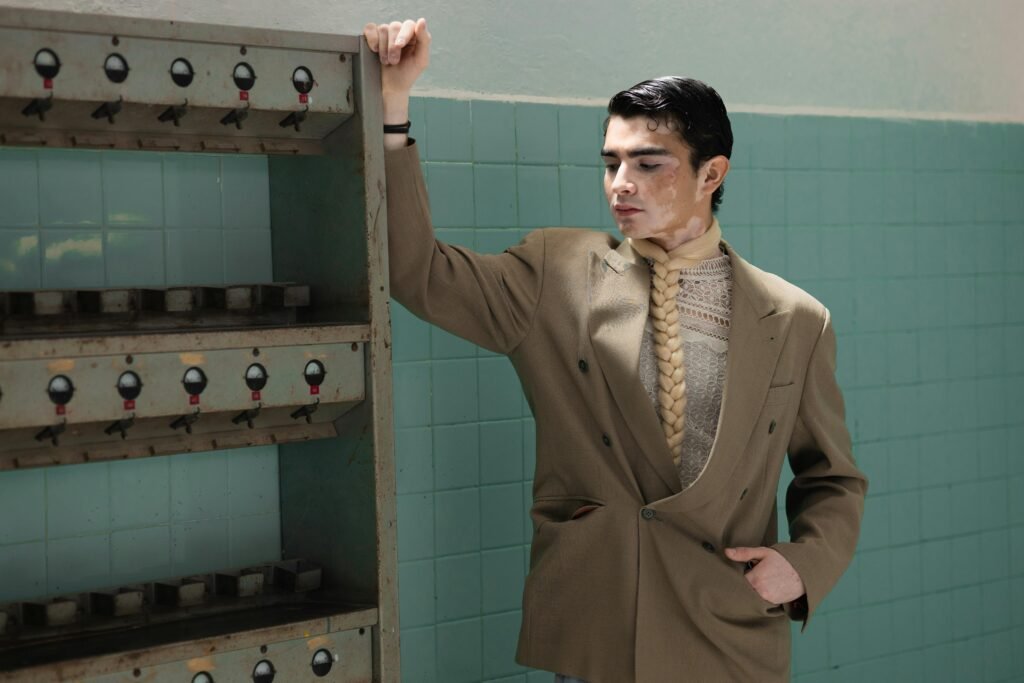

This image is property of images.pexels.com.

Introduction to Hair Weave Manufacturing

Hair weave manufacturing refers to the process of creating extensions or additional hairpieces that are sewn or bonded into a person’s natural hair. These extensions are used to add length, volume, or different styles to the hair. Hair weaves have become increasingly popular in recent years, with more and more people embracing them as a way to enhance their natural beauty and explore different looks.

Definition of Hair Weave

A hair weave is a hair extension method where additional hair is sewn or bonded onto the natural hair. The added hair can be made from synthetic fibers or human hair. It is attached to the existing hair to create a seamless and natural look. Hair weaves come in various styles, textures, and lengths, making them a versatile choice for individuals looking to change their hairstyle.

Importance of Quality in Hair Weave Manufacturing

When it comes to hair weaves, quality is paramount. A high-quality hair weave can make a significant difference in achieving a natural look and ensuring durability and longevity. Inferior quality hair weaves often result in an artificial appearance and may not withstand daily wear and styling. Therefore, it is crucial for manufacturers to prioritize quality throughout the manufacturing process to meet the expectations and demands of consumers.

Overview of the Hair Weave Manufacturing Process

The hair weave manufacturing process involves several steps to create a product that meets the desired specifications. It typically starts with sourcing the raw materials, whether it be natural human hair or synthetic fibers. The hair is then cleaned, processed, and sorted based on length, texture, and color. The next step involves either handsewing or machine-making the hair weave, depending on the preferred technique. Finally, the finished product undergoes quality control measures before being packaged and distributed to consumers.

Traditional Hair Weave Manufacturing Techniques

Hair weave manufacturing has evolved over time, with traditional techniques serving as the foundation for the industry. These techniques include handsewn hair weaves and machine-made hair weaves.

Handsewn Hair Weaves

Handsewn hair weaves involve a meticulous process where individual strands of hair are sewn onto a foundation material, such as a net or weft. This technique allows for precise control over the placement and distribution of the added hair. Handsewn hair weaves are known for their natural appearance and versatility, as they can be customized to match the client’s natural hair.

Machine-made Hair Weaves

Machine-made hair weaves, on the other hand, utilize advanced machinery and technology to create hair extensions in a more efficient and cost-effective manner. This technique involves sewing or bonding the hair onto a weft using automated processes. Machine-made hair weaves are often favored for their consistent quality and faster production time.

Pros and Cons of Traditional Techniques

Both handsewn and machine-made hair weaves have their advantages and disadvantages. Handsewn hair weaves offer the flexibility to create a highly customized and natural-looking result. However, they require skilled craftsmanship and can be time-consuming to produce. Machine-made hair weaves, on the other hand, provide consistency and efficiency but may lack the same level of customization and attention to detail.

This image is property of images.pexels.com.

Challenges in Hair Weave Manufacturing

While traditional techniques have served the industry well, there are several challenges that manufacturers face when it comes to hair weave manufacturing. These challenges include matching hair texture and color, ensuring durability and longevity, and addressing customer preferences.

Matching Hair Texture and Color

One of the primary challenges in hair weave manufacturing is ensuring that the added hair matches the client’s natural hair texture and color seamlessly. Different hair textures, such as straight, wavy, or curly, require specific techniques to replicate accurately. Similarly, achieving the right color match can be complex, as hair comes in a wide range of shades and undertones.

Ensuring Durability and Longevity

Hair weaves should be durable and long-lasting to withstand daily wear, styling, and washing. Weak or low-quality hair weaves may start to shed, tangle, or lose their shape over time. Manufacturers must invest in high-quality materials and manufacturing techniques to create hair weaves that can withstand the test of time.

Addressing Customer Preferences

Hair weave manufacturers need to adapt to changing customer preferences and trends. From different hair lengths to various styles and textures, consumers have diverse choices when it comes to selecting a hair weave. Manufacturers must stay abreast of market demands and innovate their techniques to offer a wide range of options to cater to the evolving needs of consumers.

Advanced Hair Weave Manufacturing Techniques

To overcome the challenges faced in traditional hair weave manufacturing, several advanced techniques have emerged in recent years. These techniques utilize innovative approaches and technology to enhance the overall quality, natural look, and durability of hair weaves.

1. Seamless Integration Technique

The seamless integration technique involves attaching individual hair strands to the client’s natural hair using a micro-link or tape-in method. This technique offers a seamless and nearly undetectable result, allowing the added hair to blend seamlessly with the natural hair. It provides a lightweight and comfortable experience for the wearer.

2. Strand-by-Strand Weaving Technique

The strand-by-strand weaving technique involves attaching individual strands of hair directly to the natural hair using tiny, discrete braids or micro-rings. This technique offers maximum flexibility and natural movement, as each strand is attached separately. It allows for a highly customizable result, making it suitable for clients seeking specific styles or adding volume to specific areas of the hair.

3. Invisible Knot Technique

The invisible knot technique involves tying individual hair strands onto a foundation material using an invisible knotting method. This technique creates a virtually undetectable result, as the knots are concealed within the foundation material. It is particularly beneficial for clients who desire a natural-looking hairline or parting.

4. Pre-Bonded Hair Weave Technique

The pre-bonded hair weave technique involves attaching the added hair to the client’s natural hair using a special glue or heat. This technique offers a secure and long-lasting result, as the pre-bonded extensions are designed to withstand regular washing, styling, and daily activities. It is a popular choice for clients looking for a convenient and low-maintenance hair weave option.

5. Lace Frontal Technique

The lace frontal technique involves attaching a lace frontal piece to the client’s natural hairline, creating a seamless hairline and parting. This technique allows for a highly realistic result, giving the appearance of hair growing directly from the scalp. It provides versatility in styling and can be customized to suit different hair textures and colors.

This image is property of images.pexels.com.

Benefits of Advanced Techniques

The integration of advanced hair weave manufacturing techniques offers several benefits for both manufacturers and consumers.

Enhanced Natural Look and Feel

Advanced techniques result in hair weaves that closely resemble natural hair in terms of appearance, texture, and movement. The added hair seamlessly blends with the natural hair, creating a virtually undetectable result. This enhances the overall natural look and feel, boosting the wearer’s confidence.

Improved Durability and Longevity

One of the primary advantages of advanced techniques is the improved durability and longevity of hair weaves. These techniques utilize high-quality materials and innovative attachment methods to create hair weaves that can withstand daily wear, styling, and washing. This ensures that the hair weave remains in excellent condition for an extended period, providing long-lasting value to the wearer.

Increased Variety and Customization Options

Advanced techniques offer a broader range of hair textures, styles, lengths, and colors to choose from. Manufacturers can cater to a diverse range of consumer preferences by offering customization options. Clients can select a hair weave that aligns with their individual style and desired look, creating a personalized and unique experience.

Reduced Installation Time and Effort

Advanced techniques often streamline the installation process, reducing both time and effort required for hairstylists and clients. The use of innovative attachment methods and technologies allows for faster and more efficient application of hair weaves. This benefits both the hairstylists, who can serve more clients in less time, and the clients, who spend less time in the salon chair.

Integration of Advanced Techniques

To fully harness the benefits of advanced hair weave manufacturing techniques, several factors need to be considered, including the role of technology, training and skill development for manufacturers, and collaboration with hairstylists and salons.

Role of Technology in Advanced Hair Weave Manufacturing

Technology plays a crucial role in advancing hair weave manufacturing techniques. Innovative tools, machinery, and software can enhance the precision, speed, and consistency of the manufacturing process. Manufacturers need to invest in state-of-the-art equipment and stay updated with the latest technological advancements to ensure they stay at the forefront of the industry.

Training and Skill Development for Manufacturers

As advanced techniques continue to evolve, it is essential for manufacturers to invest in training and skill development for their workforce. Ensuring that the manufacturing team is well-trained and knowledgeable about the latest techniques and technologies will result in high-quality hair weaves and satisfied customers. Manufacturers can collaborate with industry experts and trainers to provide comprehensive training programs for their employees.

Collaboration with Hairstylists and Salons

Collaboration between hair weave manufacturers and hairstylists/salons is vital to ensure the successful integration of advanced techniques. Hairstylists are at the forefront of client interactions, and their expertise and feedback are invaluable in refining and improving the manufacturing process. Manufacturers can work closely with hairstylists and salons to gather insights, conduct trials, and receive feedback on the performance and usability of different hair weave techniques.

Quality Control in Hair Weave Manufacturing

Maintaining high-quality standards is crucial in hair weave manufacturing to ensure customer satisfaction, product reliability, and regulatory compliance. Manufacturers must implement robust quality control measures throughout the manufacturing process.

Testing and Evaluation of Raw Materials

The first step in quality control is the rigorous testing and evaluation of raw materials. This includes testing the hair for strength, texture, and color consistency. Manufacturers should work closely with reputable suppliers to source high-quality hair and thoroughly inspect it before incorporating it into the manufacturing process.

Quality Assurance During the Manufacturing Process

Quality assurance should be incorporated at every stage of the manufacturing process. This involves regular inspections, sample testing, and meticulous record-keeping to identify and rectify any potential defects. Manufacturing teams should undergo continuous training and adhere to standard operating procedures to maintain consistency and avoid manufacturing flaws.

Third-Party Certifications and Industry Standards

Seeking third-party certifications and complying with industry standards can further demonstrate a manufacturer’s commitment to quality. Certifications from reputable organizations or adherence to industry-specific standards help build trust with consumers and ensure compliance with safety and quality regulations.

Market Trends and Innovations

The hair weave industry is dynamic, with market trends and innovations constantly driving its evolution. Staying updated with these trends and innovations is essential for manufacturers to remain competitive and meet the ever-changing demands of consumers.

Emerging Hair Weave Trends

Currently, the market is witnessing a growing demand for natural-looking hair weaves that blend seamlessly with the wearer’s natural hair. Styles like balayage, ombre, and vibrant hair colors are also trending. Manufacturers need to keep up with these trends and offer products that cater to the desire for realistic and eye-catching hairstyles.

Innovative Techniques in Demand

Innovative techniques that offer convenience, versatility, and customization options are in high demand. Techniques like the invisible knot technique and lace frontal technique are gaining popularity due to their ability to create a natural hairline and parting. Manufacturers should invest in research and development to identify emerging techniques that provide unique benefits to consumers.

Sustainability and Ethical Considerations

As consumers become more conscious about sustainability and ethical practices, manufacturers need to address these considerations. Using ethically sourced human hair or sustainable synthetic fibers can appeal to environmentally conscious consumers. Manufacturers should also consider environmentally friendly packaging and production processes to minimize their ecological footprint.

Consumer Education and Awareness

With the abundance of information available, educating consumers about advanced techniques in hair weave manufacturing is crucial. Providing accurate and comprehensive information can help consumers make informed decisions and dispel any misconceptions surrounding hair weaves.

Educating Consumers about Advanced Techniques

Manufacturers can play a significant role in educating consumers about the benefits and intricacies of advanced hair weave manufacturing techniques. This can be done through informative product packaging, online resources, social media campaigns, and collaborations with influencers or hairstylists. By providing clear and accessible information, manufacturers can empower consumers to make educated choices about the hair weaves they purchase.

Exploring the Benefits and Drawbacks

It is also essential to provide a balanced perspective on the benefits and drawbacks of advanced techniques. While these techniques offer many advantages, they may not be suitable for everyone or every specific hair type. By openly discussing the limitations and potential challenges, consumers can make decisions that align with their individual needs and preferences.

Addressing Common Misconceptions

Hair weaves often carry misconceptions and stigma attached to them. Manufacturers can address these misconceptions through educational content that dispels myths and provides accurate information. This can help consumers make informed decisions and foster a positive perception of hair weaves as a versatile and transformative beauty accessory.

Conclusion

The integration of advanced techniques in hair weave manufacturing has revolutionized the industry, allowing for enhanced natural looks, improved durability, increased customization options, and reduced installation time. By utilizing state-of-the-art technology, implementing rigorous quality control measures, and collaborating with hairstylists, manufacturers can deliver high-quality hair weaves that meet the diverse needs and preferences of consumers. As the industry continues to evolve, manufacturers must stay innovative, adapt to market trends, and prioritize consumer education and awareness to unlock the full potential of advanced hair weave manufacturing techniques. With a focus on quality, creativity, and consumer satisfaction, the future prospects of hair weave manufacturing are full of potential advancements and opportunities for growth.